CSR Performances

Content

The interest in and regulations on the environment, safety and health have been constantly increasing at home and abroad. Against this backdrop, companies are required to disclose information on the environmental impact of their business activities and to make efforts for improvement. Also, they need to do their business in a sustainable way by creating a safe and healthy working environment.

Our Approach

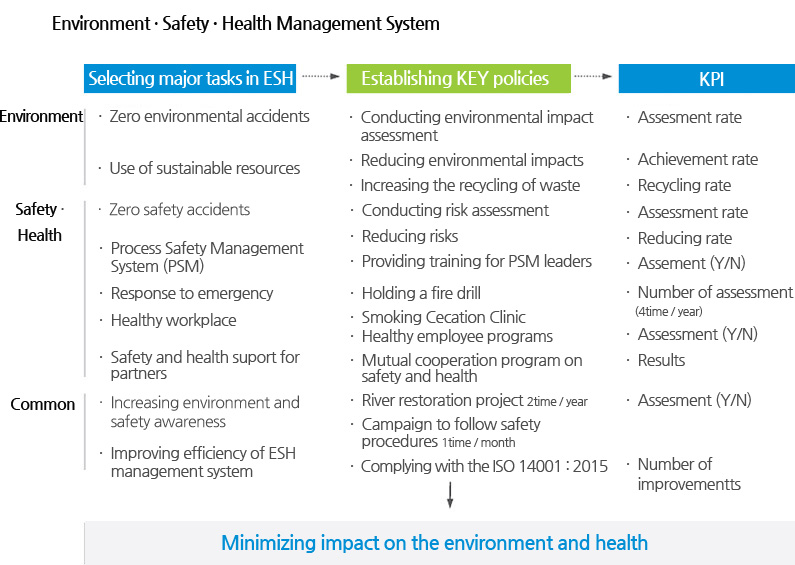

ISU PETASYS has established the ESH policies to minimize the environmental impact during the production and distribution process and to establish a safe and healthy working environment, and implemented the policies by operating the environment, safety, and health management system (ISO 14001, OHSAS 18001).

Management System

Based on the EnvironmentㆍSafetyㆍHealth Integrated Management System, ISU PETASYS has systematically managed the environmental impact of its business activities and established a safe working environment. Complying with the ESH regulations, the company has selected major tasks in the environmentㆍsafetyㆍhealth areas, and implemented key policies.

Environmental Management System

In order to strengthen the management of chemicals and waste that might negatively affect the health and safety of employees and the environment, ISU PETASYS has extended the scope of environmental assessment to the entire process, ranging from materials to product disposal, and reflected the results of assessment on improvement activities.

Climate Change Mitigation

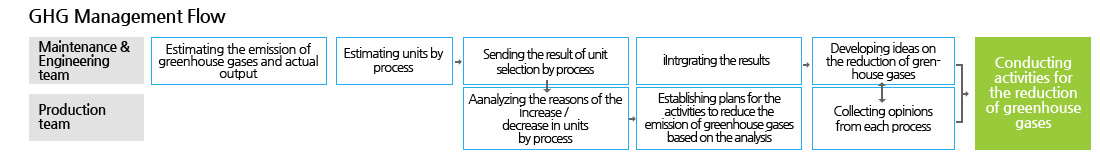

ISU PETASYS has created a greenhouse gas inventory according to the National GHGs Management System (NGMS) to estimate and manage the emission of greenhouse gases, and also conducted various activities to reduce the amount of direct and indirect emissions.

Safety and Health Management System

ISU PETASYS has adopted the Occupational Health and Safety Management System (KOSHA 18001, OHSAS 18001) and complied with the internal safety and health regulations to create a safe and healthy workplace. The company has strived for health and safety management ranging from risk prevention to program operation to monitoring. In addition, the company has operated the working-level committee for safety and health management that consists of supervisors and representatives of partner companies to create a safe and healthy workplace.

ESH KPIs

| KPI | Unit | 2018 | 2019 | 2020 | 2021 | 2022 |

|---|---|---|---|---|---|---|

| GHG Emission Scope1 | tCo2eq | 23,840 | 17,415 | 24,012 | 23,082 | 11,285 |

| GHG Emission Scope2 | tCo2eq | 30,690 | 29,328 | 28,868 | 28,104 | 29,685 |

| Energy consumption Scope1 | TJ | 142 | 119 | 144 | 110 | 117 |

| Energy consumption Scope2 | TJ | 632 | 604 | 600 | 587 | 620 |

| (Waste Discharge (General) | Ton | 4,034 | 4,884 | 5,155 | 6,901 | 7,538 |

| Waste Discharge (Designated) | Ton | 4,113 | 3,973 | 7,283 | 4,352 | 4,855 |

| Waste recycling rate | % | 86 | 90 | 89 | 82 | 85 |

| Air pollutant emission-Nox | kg | 1,306 | 5,953 | 1,142 | 1,362 | 554 |

| Air pollutant emission-Ammonia | kg | 837 | 1,824 | 3,766 | 5,658 | 5,837 |

| Wastewater discharge | Ton | 1,119,162 | 973,523 | 1,139,434 | 1,157,404 | 1,220,862 |

| Water pollutant emission(COD) | kg | 62,023 | 49,773 | 74,234 | 68,560 | 52,781 |

| Water pollutant emission(SS) | kg | 11,025 | 10,217 | 15,206 | 11,446 | 20,681 |

| Water pollutant emission(T-N) | kg | 29,470 | 39,682 | 45,639 | 59,506 | 55,091 |

| Water pollutant emission(Cu) | kg | 284 | 318 | 980 | 656 | 806 |

| Water consumption | Ton | 1,251,397 | 1,281,440 | 1,297,159 | 1,301,918 | 1,326,252 |

| Hazardous chemicals leakage accidents | Case | - | - | - | - | - |

| Number of accidents | Case | - | - | - | - | - |

| Industrial accident rate | % | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% |

| Hazardous chemicals release | Ton | 7,569 | 8,251 | 9,062 | 9,996 | 10,346 |